TRAC Management System

Download the TRAC Management System Brochure »

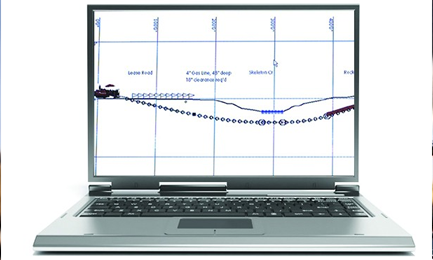

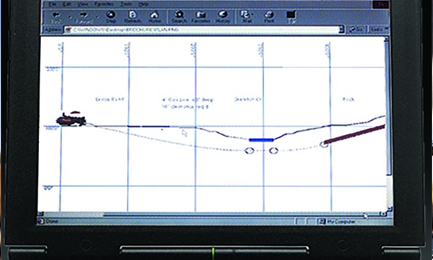

Planning a bore in advance saves time, money, and reduces complications. With Subsite® Electronics TMS Plus, a Windows®-based management tool, you can plan the bore, monitor its real-time progress, and print out a completed survey or as-built map when you're done.

- Intuitive menus and online user guide make the software easy to use.

- With TMS Plus, you can create multiple bore plans for the same job based on different units or paths.

- Works with Subsite Electronics electronic guidance equipment to create a record of the installed bore path.

- Records the drill head position each time a new drill pipe is placed in the ground, and the position of the actual product during backreaming.

- Provides quick-reference information on bend radius for more efficient use of drill pipe and installed product.

- Compiles information such as pipe number, depth estimate, drill head roll angle, pitch, directional beacon temperature and battery level, date and time.

- Supports five languages—English, German, French, Spanish and Italian—and adapts to different international settings.